The screening machine mainly classifies the finished products and is equipped with different screens according to different requirements for the finished products.

1. Simple structure: Its structure is simple and clear, easy to maintain, not prone to failure, and reduces equipment maintenance costs.

2. Improve efficiency: The drum screening machine uses a special screen with high screening efficiency. It can classify materials according to different needs and improve production efficiency.

3. Strong adaptability: The drum screening machine can be customized. According to the actual production needs of the user, drum screens of different specifications and models can be customized and have a wide range of applications.

4. Stable operation: The operation of the drum screening machine is stable, low noise, and high screening efficiency more than 95%, which improves the quality and efficiency of production.

5. Space saving: The drum screening machine occupies a small space and can maximize production efficiency in a limited space.

High Screening Efficiency. Because the equipment has a plate-type screen cleaning mechanism design. It can never block the screen, so as toimprove the screening efficiency of the equipment.

Good Working Environment If you need, we can provide you rotary screener with a closed dust cover. When this machine is working, there is nodust flying phenomenon which improve the working environment greatly.

Low Noise. With sealed dust cover, the noise generated by material and rotary screen is completely isolated.

Long Service Life. The production materials of our rotary screen machine is galvanized steel, So the service life wll be long for your fertilizer production.

Convenient Maintenance, There are observation windows on both sides of sealed dust cover. 5o, works can observe the operation of equipment at any time.

| Model | GS1.0×3.0 | GS1.2×4.0 | GS1.5×6.0 | GS1.8×8.0 |

| Cylinder diameter(mm) | 1000 | 1200 | 1500 | 1800 |

| speed(r/min) | 22 | 16 | 14 | 11.5 |

| dip angle(°) | 2-2.5 | 2-2.5 | 2-2.5 | 2-2.5 |

| power(kw) | 2.2 | 3 | 5.5 | 11 |

| capacity(t/h) | 1-3 | 2-4 | 5-10 | 20-30 |

| dimension L*W*H(m) | 4x1.4x2.6 | 5.2x0.6x2.6 | 7.2x2x3.0 | 9.3x2.3x3.2 |

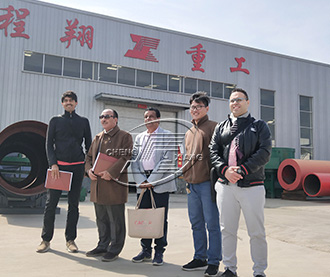

since 1995

Nearly 30 years of international trade experience

80+ countries and regions

1000+ international partners

20,000m2 workshop

60+ sets of advanced processing equipment

20+ technical engineers

200+ skilled manufacturing workers

Our fertilizer equipment is exported to more than 80 countries and regions like Russia, Germany, Malaysia, Pakistan, Colombia, Uruguay, Sri Lanka, Philippines, Iraq, Honduras, Saudi Arabia, Nigeria, Dominica, South Korea, and Switzerland, etc.

We Use Export Standard Plywood Boxes Or Bubble Plastic Packaging According To Product Categories, And Use Export Standard Triangular Wood And Rope fixation According To Different Transportation Needs.

●28+ production and export experience.

●20+ technical engineers,200+ skilled manufacturing workers, Ensure high quality and output

●There are various types and models available, and customization is also possible

●13+:We have been cooperating with Alibaba for 13 years

●80+:exporting to over 80 countries and regions

●1000+:serving over 1000 international customers

Yes, we provide guidance on installation and training

The English manual book and video will be provide for showing how to resolve the problems, if necessary, we will dispatch our engineer to your factory.

●10,000-500,000 t/y NPK compound fertilizer production line

●10,000-200,000 t/y organic fertilizer production line

●10,000-200,000 t/y BB blending fertilizer production line