The organic fertilizer pellet making machine is mainly cover of equipment that ferments and decomposes the cow dung, chicken manure, sheep manure and other livestock and poultry plus straw, etc. in proportion, and then makes it into powder or granules to meet the soil's demand for organic matter. It can be divided into fermentation section and granulation section.

Compost turner :

Regular turning to accelerate fermentation speed.

Feeding bin for loader :

mainly plays the role of uniform feeding and initial crushing.

Crusher :

crush large pieces of materials into powder to facilitate later granulation.

Mixer :

add all the required ingredients and mix evenly.

Granulator :

converts powder into granules for easy storage, transportation, and spreading.

Rotary drying machine :

It is used to dry wet granules

Rotary cooling machine :

It is used to cool the temperature of materials

coating machine :

It makes the granules look brighter

Screening machine :

Screen out the required particle size, and return the unqualified ones to granulation again.

Automatic packaging machine:

no manual weighing required, accurate weighing.

| Annual output (tons) | area Fermentation site | area granulation site | type of Granulator | Approximatet total power | Quantity of core equipmnet |

| 10,000 | 200㎡ | 400㎡ | Disc Granulator | 65KW | 9 |

| Striring teeth granualtor | 105KW | 9 | |||

| 20,000 | 200㎡ | 400㎡ | Disc Granulator | 90KW | 10 |

| 300㎡ | Striring teeth granualtor | 135KW | 10 | ||

| Three in one Granulator | 115KW | 10 | |||

| 30,000 | 300㎡ | 500㎡ | Disc Granulator | 135KW | 15 |

| Three in one Granulator | 180KW | 15 | |||

| 50,000 | 1000㎡ | 1000㎡ | Disc Granulator | 260KW | 16 |

| Three in one Granulator | 320KW | 16 |

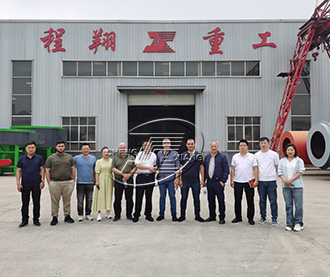

since 1995

Nearly 30 years of international trade experience

80+ countries and regions

1000+ international partners

20,000m2 workshop

60+ sets of advanced processing equipment

20+ technical engineers

200+ skilled manufacturing workers

Our fertilizer equipment is exported to more than 80 countries and regions like Russia, Germany, Malaysia, Pakistan, Colombia, Uruguay, Sri Lanka, Philippines, Iraq, Honduras, Saudi Arabia, Nigeria, Dominica, South Korea, and Switzerland, etc.

We Use Export Standard Plywood Boxes Or Bubble Plastic Packaging According To Product Categories, And Use Export Standard Triangular Wood And Rope fixation According To Different Transportation Needs.

●28+ production and export experience.

●20+ technical engineers,200+ skilled manufacturing workers, Ensure high quality and output

●There are various types and models available, and customization is also possible

●13+:We have been cooperating with Alibaba for 13 years

●80+:exporting to over 80 countries and regions

●1000+:serving over 1000 international customers

Yes, we provide guidance on installation and training

The English manual book and video will be provide for showing how to resolve the problems, if necessary, we will dispatch our engineer to your factory.

●10,000-500,000 t/y NPK compound fertilizer production line

●10,000-200,000 t/y organic fertilizer production line

●10,000-200,000 t/y BB blending fertilizer production line