OVERVIEW

Nowadays, starting an organic fertilizer production line under the guidance of right business plan can improve supply of non-harmful fertilizer to farmers, and it has been found that the benefits of using organic fertilizer are far outweigh the cost of organic fertilizer plant setup, not only referring to economic benefits, but also including environment and social efficiency. Switching organic wastes to organic fertilizer can help farmers to extend soil life, improve water quality, boost crop production and eventually increase their yields. Then it is of the essence for investors and fertilizer manufacturers to learn how to make waste into fertilizer and how to start organic fertilizer business. Here, I will discuss the points that need attention from the following aspects when starting organic fertilizer plant.

TO BUSINESS OWNER:

Why Do You Start Organic Fertilizer Making Project

· Organic Fertilizer business being profitable

Global trends in the fertilizer industry point to environmentally safe and organic fertilizers that maximize crop yields and minimize lasting negative impacts on the environment, soil and water. Another side, It is well known the organic fertilizer as an important agriculture factor has a huge market potential, with the development in agriculture, the benefits of organic fertilizer are increasingly conspicuous. In this view, it is profitable and feasible for entrepreneur/investors to start organic fertilizer business.

· Government support

In recent years, governments have provided a series initiative support for organic farming and organic fertilizer business, including target subsidies, market investments, capacity expansion and financial assistance, all of which can promote the wide use of organic fertilizers. For instance, Indian government offers the promotion of organic fertilizer up to Rs.500/per hectare, and in Nigeria, the government is committed to taking the necessary steps for promoting the use of organic fertilizer in order to develop Nigerian agriculture ecosystem for creating sustainable jobs and wealth.

· Awareness of organic food

People are becoming more aware of the safety and quality of the daily food. The demand for organic food has grown in the past ten years in a row. It is fundamental to protect food safety through using organic fertilizer to control the production source and avoid soil pollution. Therefore, the increasing of consciousness for organic food is also conducive to the development of organic fertilizer production industry.

· Plentiful raw materials of organic fertilizer

There are large volumes of organic waste are generated daily all over the world. Statistically, there are more than 2 billion tons of waste globally each year. Raw materials for producing organic fertilizer are plentiful and extensive, such as agriculture wastes, like straw, soybean meal, cottonseed meal and mushroom residues), livestock and poultry manure (like cow dung, pig manure, sheep muck, horse dung and chicken manure), industrial waste (like vinasse, vinegar, residue, cassava residue and sugarcane ash), household garbage (like food waste or kitchen garbage) and so on. It is the plentiful raw materials that makes organic fertilizer business popular and prosperous in the world.

HOW TO CHOOSE THE SITE LOCATION

Proposed Site of Organic Fertilizer Plant

The choice of site location for organic fertilizer plant should follow the principles:

· It should be situated in close proximity to the supply of raw materials for organic fertilizer production, aiming at reducing transport cost and transportation pollution.

· Factory should be located in area with convenient transportation so as to reduce logistical challenges and transport cost.

· The proportion of plant should satisfy the requirement of production technology process and reasonable layout, and leave appropriate space for further development.

· Keep away from residential area to avoid affecting the lives of residents because there are more or less special odor generated during the process of organic fertilizer production or raw materials transportation.

· It should be located in places that are flat region, hard geology, low water table and excellent ventilation. In addition, it should avoid places that prone to slides, flooding or collapse.

· The site should be adapted to local conditions and land conservation. Make full use of idle land or wasteland and does not occupy farmland. Use the original unused space as much as possible, and then you can reduce investment.

· The organic fertilizer plant is preferably rectangular. Factory area should be about 10,000-20,000㎡.

· The site cannot be too far away from the power lines in order to reduce power consumption and investment in the power supply system. It should be near water supply so as to meet the needs of production, living and fire water.

In a word, the source materials require to establish the industry, especially poultry manure and plant waste, should be really available from the market place and poultry farms in close proximity to the proposed plant.

SURVEY OF ORGANIC FERTILIZER MATERIALS

The main goal of organic fertilizer plant is to produce organic fertilizer that use a variety of materials containing organic matters and nitrogen, phosphorous and potassium in plant growth. Before starting, you need to make an investigation of the local organic raw materials market. To make a survey of needed information for site construction, e.g., the kind of materials, acquisition and transportation ways and shipping cost.

The most essential thing to realize continuous organic fertilizer production is to promise the incessant supply of organic raw materials. Due to the characteristics of big volume and difficulty in transportation of raw materials, it had better to establish your site with sufficient organic raw materials supply.

There are so many common organic materials, the investor usually choose the most abundant one as the main raw materials of their organic fertilizer, and use other organic raw materials or moderate NPK elements as additives, for example, an organic fertilizer site established near a farm, and there are plenty of agriculture waste every year, this investor would like to choose crops straw as his main raw materials, and animal manure, peat and zeolite as accessories.

In short, organic materials, containing organic matters and nutrients which are necessary to promote the growth of crops, can be used as raw materials in organic fertilizer production process. Production technology can be designed according to different raw materials.

HOW TO CHOOSE MACHINES FOR ORANIC FERTILIZER PRODUCTION PLANT

Proper scale of Organic Fertilizer Production Plant

For new investors, Mini organic fertilizer production line is a better choice. This line is with smaller production capacity-about 700 kg per hour.

It is a relatively long process of organic fertilizer production. To use livestock manure as organic fertilizer materials, it usually takes 7 days for fermentation. The investment in site and machinery is huge. If the production scale is too large, the semi-diameter of raw material acquisition will increase and raw material transportation costs are high. Therefore, if the scale of production of organic fertilizer plant is more than 1,000 tons of pure organic fertilizer, you should consider build the site in areas that are rich in organic materials.

Paying attention to the degree of process automation

It is poor of working conditions in organic fertilizer production line. Labors are in heavy workload. Process automation should be increased in production. However, labors cost should be reduced. Modern science and technology provide possibility of process automation for organic fertilizer production. Meanwhile, machinery cost, running cost and maintenance cost are increasing accordingly. Therefore, you should choose proper process automation according to economic benefits rather than one-sided pursuit of production automation.

Our Suggestion

For the starters who have limited capital invest, we propose plant with small scale production as your best choice. Taking 800kg/h organic fertilizer production plant with quite low initial investment for instance, this plant include: groove compost turner, semi-wet crusher, horizontal mixer, disc granulating machine, screening machine and automatic packaging machine.

THE KEY FACTORS THAT AFFECTING ORGANIC FERTILIZER QUALITY

In organic fertilizer manufacturing process, manure compost and fermentation of organic wastes are the core technology, which aims to create a better environment condition for normal microbial breeding, to promote microbial metabolic process, to accelerate decomposition and transformation of organic wastes, to kill pathogens and parasite eggs, and finally granulate quality commercial granular organic fertilizers. In organic wastes fermentation, there are 5 factors affecting the final quality of the organic compost, which will directly influence the final quality of the granulated organic fertilizer. They are Water, Temperature, C/N ration, Ventilation and oxygen supplying, and pH, which are environmental factors. While in the whole fermentation process, by artificially control of fermentation and organic compost conditions, creating suitable environment for aerobic activity, and promote rapid fermentation of raw materials, standardized commercial organic fertilizers will be manufactured.

ENVIRONMENTAL BENEFITS FROM ORGANIC FERTILIZERS

Plant Growth

Organic fertilizers can be easily produced by fertilizer granulator. It provides nutrients necessary for plant growth, with the benefit of being slower-acting and gentler than chemical fertilizers, so that you are less likely to overfeed and chemically burn your plants. Organic fertilizers are not in a form that is immediately absorbed by plants, but rather must be first broken down by soil bacteria and fungi into forms that plants can absorb. This means that, unlike chemical fertilizers, organic fertilizers are not easily washed away in a heavy rainstorm or irrigation session, and that the plants get the benefit of nutrients for growth more evenly over a longer period of time rather than all at once.

Soil Improvement

Increasing organic matter content & the nutrient uptake and utilization in crops, reducing soil hardening, improving soil fertility. Applying organic fertilizer into the soil, organic matter can efficiently improve physical and chemical properties of soil, preserve fertility, and create sound soil-environment for the growth of crops. While chemical fertilizers simply add water-soluble chemicals which are either absorbed by the plant roots or leach away, potentially polluting water resources, organic fertilizers add organic matter that helps the soil to retain moisture and nutrients.

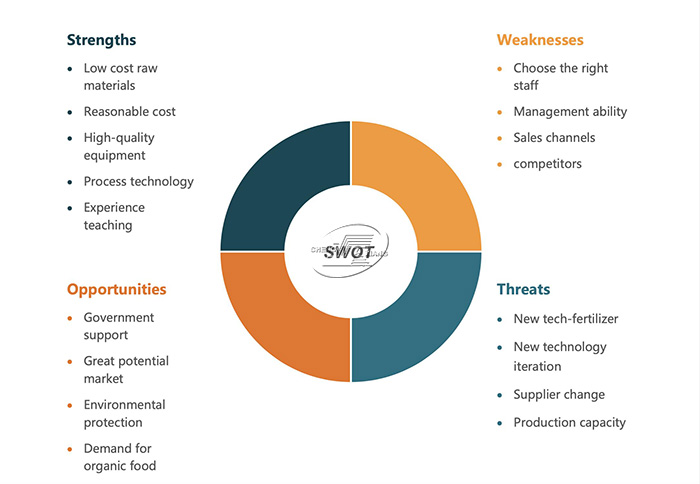

SWOT ANALYSIS